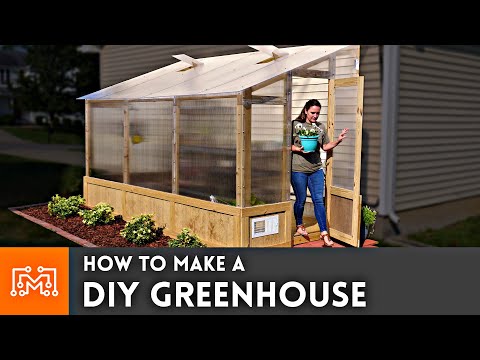

How to Make a DIY Greenhouse | I Like To Make Stuff

We helped Josh’s wife make a DIY Greenhouse with help from Lowe’s. It was a fun & challenging build, but Lowe’s is the perfect partner to help you finish your fall projects and

get back to enjoying what matters. Look below for everything we used in this project!

TOOLS & SUPPLIES (affiliate links):

Sunlite Polycarbonate Sheets: https://low.es/2lSHmi0

Brown Engineered Panel Siding: https://low.es/2lGodjh

Tuftex 6mm H Channel: https://low.es/2m2Z4jd

National Hardware Spring Hinges: https://low.es/2mdLGcd

Kreg Accu-Cut: https://low.es/2kc1R93

30 Seconds Outdoor Cleaner: https://low.es/2kktdKt

Bostitch Framing Nailer: https://low.es/2lErLTa

DeWalt 20-volt Circular Saw: https://low.es/2kcS3vD

DeWalt 20-volt Jigsaw: https://low.es/2ksOmSJ

DeWalt Drill & Driver Combo: https://low.es/2lP7Cdu

DeWalt Miter Saw: https://low.es/2lQLVcF

Union Washer Wood Screws: https://low.es/2kktFs9

Keter Shelving Unit: https://low.es/2lE6bOY

Accord Ventilation Register: https://low.es/2lzw4iK

AcuRite Digital Thermometer: https://low.es/2m1VOod

https://kit.co/iliketomakestuff/my-woodworking-tools

https://kit.co/iliketomakestuff/shop-safety-gear

MUSIC: http://share.epidemicsound.com/iltms

Josh’s wife is really into gardening and planting beautiful greenery leading to her desire for a greenhouse. This way, she can keep her plants alive during the winter months and incubate some new plants so they’re ready for the spring.

Josh began the design with a 3d model in Fusion 360. We got our bill of materials and the cut list then headed to our local Lowe’s to get the supplies to begin framing the structure. I chose to use pressure treated lumber for this exterior addition to resist the moisture and humidity that may build up inside the greenhouse. Using Josh’s measurements, we nailed together the floor and added the front and back wall studs.

Before adding a structure to your yard, you may chose to grate and level the area beforehand. Josh didn’t want to tear up the yard, and here in Kentucky, the clay is super hard. In lieu of digging into the ground to level it, we chose to level the floor frame by adding 2×4 posts semi-driven into the ground. This way, Josh and i could level the floor and nail it to those posts along the span of the greenhouse. Now that we had a level surface to work from, we continued to build out the frame by connecting the front and back studs and then connecting those two walls with some ceiling joists.

For the greenhouse floor, Josh wanted something that could resist any standing water that would fall down from the plants. We found some engineered siding panels at Lowe’s that are weather-resistant and come in large, 4′ x 8′ sheets. These panels are only 3/8″ thick, so we added another layer of pressure treated 1/2″ plywood to ensure the floor was strong enough to walk on. We fit three of these double-layered panels on top of the floor frame, making sure to cut around the wall studs and secured them with screws.

For the greenhouse’s exterior, it is possible to simply cover the bare frame with the clear polycarbonate sheets, but because of this greenhouse’s size, that would take more than the 10 panels we allotted for this project. We had to order the sheets from Lowes.com and the came in a pack of 10. So rather than sacrificing the size of the greenhouse, Josh got creative and added a decorative element to the outside that helped use less polycarbonate.

We decided to use the cutoffs of the engineered, exterior sheeting to make a skirting of wood panels that wrapped around the greenhouse. To cover any seams and to give the element some definition, Josh cut up some 1×4 trim pieces that really set the decorative element apart. It looked really nice and flowed super well with the overall design. Again, these step is optional, but it does look fantastic and it helps save on the more expensive material later.

At this point in the project, we have a nice looking frame of a greenhouse. To make it functional as a greenhouse, we need a way to trap the radiant heat from the sun inside the structure. We found many ways to do this from using reclaimed windows, rolls of plastic tarp pulled tight, glass panes, and sheets of acrylic.

Read more at : https://iliketomakestuff.com/how-to-make-a-diy-greenhouse/

#greenhouse #diy #how-to

Subscribe: http://bit.ly/ILikeToMakestuffSubscribe

Check out my TopVideos!: http://bit.ly/ILikeToMakeStuffTopVideos

Learn 3d modeling, get digital plans, and cool merch at

https://iliketomakestuff.com

Want to support ILTMS? Get exclusive content and more…

http://www.iliketomakestuff.com/patreon

FOLLOW:

http://instagram.com/iliketomakestuff

http://twitter.com/iliketomakestuff

http://facebook.com/iltms

#ILikeToMakeStuff

How to Make a DIY Greenhouse | I Like To Make Stuff

https://www.youtube.com/watch?v=sQWPnaiixe0

I Like To Make Stuff

http://www.youtube.com/Iliketomakestuff